Views: 0 Author: Site Editor Publish Time: 2025-12-22 Origin: Site

Chromium alloy liners are essential components in many industrial grinding mills, providing superior protection to mill shells from wear and tear caused by grinding media and abrasive materials. Their high abrasion resistance, toughness, and long-lasting durability make them particularly suited for high-wear applications in industries like mining, cement, and quarrying. Proper installation of these liners is crucial to ensure their optimal performance, efficiency, and longevity. This article will provide a step-by-step guide on how to properly install chromium alloy liners, outline the necessary tools and materials, and highlight best practices to ensure a smooth installation process and minimize potential issues.

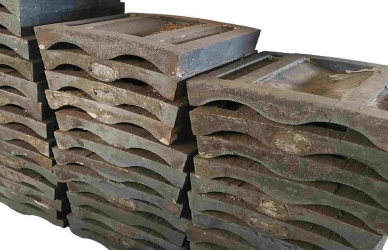

Chromium alloy liners are made from a mix of iron and chromium, typically containing 12% to 30% chromium. This high chromium content provides exceptional abrasion resistance and high hardness, making them ideal for high-wear applications in grinding mills. Their robust composition allows them to perform under harsh grinding conditions where other liners would wear quickly.

The key benefits of chromium alloy liners are:

Abrasion Resistance: The high chromium content offers superior abrasion resistance, making them perfect for high-impact environments.

High Hardness: These liners maintain their shape and structure under extreme grinding conditions.

Toughness: They are tough enough to handle shock impacts without cracking, suitable for aggressive grinding.

Longer Service Life: Their wear resistance ensures a longer lifespan than traditional liners, reducing maintenance and replacement costs.

Chromium alloy liners are used in industries where grinding mills face heavy wear:

Mining: Protects mills grinding ores and hard minerals like gold and copper.

Cement Production: Ideal for clinker grinding mills where high abrasion is common.

Quarrying: Protects mills processing hard rocks and aggregates.

These industries benefit from chromium alloy liners by achieving extended liner life, improved grinding efficiency, and reduced downtime due to fewer replacements.

Proper installation of chromium alloy liners requires several specialized tools to ensure that the liners are securely and accurately placed. Key tools include:

Wrenches: Adjustable wrenches and socket wrenches are needed to tighten bolts and fasteners securely.

Screwdrivers: For smaller fasteners and adjustments, screwdrivers may be required.

Lifting Equipment: Given the weight of chromium alloy liners, proper lifting equipment, such as cranes, hoists, or forklifts, is essential to safely handle and position the liners.

Measuring Tools: Accurate measurement tools like calipers, measuring tapes, and laser alignment tools are needed to ensure correct alignment and positioning of the liners.

Torque Wrenches: To ensure that bolts are tightened to the manufacturer’s recommended specifications and avoid over-tightening.

In addition to tools, the following materials are essential for the proper installation of chromium alloy liners:

Bolts and Fasteners: These are critical for securing the liners in place. The size and strength of bolts must match the liner design and mill specifications.

Sealants: Depending on the mill design, sealants may be required to prevent leakage between the liner and mill shell, especially in wet milling applications.

Gaskets: In some installations, gaskets may be used to ensure a tight seal and prevent material leakage.

Lubricants: Lubricants may be used on the fasteners and threads to ensure smooth installation and avoid damage to the liner during tightening.

Before beginning the installation of chromium alloy liners, it is essential to ensure that all tools and materials are ready and in good condition. Using worn-out or improper tools can lead to misalignment, incomplete installation, or even damage to the liners or the mill shell. Additionally, checking that the correct bolts, fasteners, and sealants are available in the right sizes and quantities is crucial for a smooth installation process. Having all components properly prepared minimizes delays, ensures a secure installation, and ultimately contributes to the longevity and performance of the liners.

Before installing chromium alloy liners, it is crucial to prepare the mill shell to ensure a smooth and secure installation. The process involves:

Cleaning the Shell: Thoroughly clean the mill shell by removing any dirt, rust, or residue from previous liners. This ensures that the new liners will fit properly and prevents potential issues with alignment and stability.

Inspecting the Shell: Check the mill shell for any damage or wear that may have occurred over time. If there are cracks or significant wear, address these issues before proceeding with liner installation to ensure proper functionality.

Preparing the Mounting Surface: Ensure that the surface where the liners will be attached is smooth and free of any obstructions that could interfere with the secure placement of the liners.

Lifting and positioning chromium alloy liners requires careful handling to avoid damage:

Use Appropriate Lifting Equipment: Use cranes, hoists, or forklifts designed for heavy lifting to move the liners into position. Ensure the lifting equipment is rated for the weight and size of the liners to avoid accidents or damage.

Handling the Liners: Always use lifting straps or hooks to handle the liners. Avoid direct lifting by hand to prevent surface damage or cracking of the alloy material.

Positioning the Liners: Carefully position the liners inside the mill shell, ensuring they align with the intended liner profiles and positions. The proper placement ensures efficient grinding and minimizes wear on both the liners and the mill shell.

Once the liners are in position, it is important to securely fasten them to the mill shell:

Align the Liners: Ensure the liners are correctly aligned according to the mill design. This step is crucial for even wear distribution and optimal grinding efficiency.

Use Proper Fasteners: Attach the liners to the shell using bolts, nuts, and washers that are compatible with the liner’s material and design. Ensure the fasteners are tightened to the manufacturer’s specifications to avoid loosening during operation.

Avoid Over-tightening: While it’s important to tighten the fasteners, over-tightening can cause damage to the liners or mill shell. Use a torque wrench to ensure the correct tension.

Proper alignment and secure tightening are essential for the mill's smooth operation:

Check for Proper Alignment: After securing the liners, double-check the alignment to ensure there is no misalignment or uneven fit. Misaligned liners can lead to increased wear and inefficient grinding.

Tighten the Fasteners: Recheck the fasteners after installation to make sure they are secure but not over-tightened. Properly tightened fasteners ensure the liners stay in place during operation and prevent loose fittings, which can cause vibrations or damage.

Once the chromium alloy liners are installed, perform a final inspection to ensure everything is in proper working order:

Inspect for Defects: Check the liners for any signs of cracks, defects, or surface irregularities. Even small defects can lead to premature wear or failure during mill operation.

Verify Fastener Tightness: Ensure all fasteners are properly tightened and there are no loose bolts or nuts.

Test Movement: If applicable, test the movement of the grinding media within the mill to ensure proper liner functionality and grinding efficiency.

Check for Clearance: Make sure there is sufficient clearance between the liners and the grinding media to allow for efficient grinding and reduce the risk of damage.

Chromium alloy liners offer superior abrasion resistance and high hardness, making them more durable than steel and rubber liners. While steel is prone to faster wear and rubber suits softer materials, chromium alloy liners excel in harsh grinding conditions, providing longer service life and better impact resistance.

The lifespan of chromium alloy liners typically ranges from 6 months to 2 years, depending on grinding conditions and material hardness. Abrasive materials can reduce liner life, so regular inspection and monitoring are essential to determine the optimal time for replacement.

Yes, chromium alloy liners are suitable for both wet and dry milling. They provide excellent wear resistance in both environments, with their performance depending on the material being processed and the grinding conditions.

Chromium alloy liners require minimal maintenance, but regular inspections for wear and damage are crucial. Cleaning with non-abrasive agents and ensuring proper alignment and tightening of fasteners will help maximize their lifespan and performance.

In conclusion, proper installation of chromium alloy liners is essential to ensure long-lasting performance and optimal mill efficiency. By following best practices and using the right tools during installation, businesses can avoid premature liner wear and costly repairs, ultimately extending the life of both the liners and the mill itself. Investing in proper liner installation helps maximize the benefits of chromium alloy liners, improving overall operational efficiency and reducing downtime, which ultimately leads to significant cost savings in the long run.