High-chromium Alloyed Grinding Balls manufacturer

Welcome to Huihe Miningparts Co., Ltd! We are a trusted manufacturer dedicated to providing high-chromium alloyed grinding balls with exceptional hardness, wear resistance, and durability for mining and industrial applications.

Product Center

Products Introduce

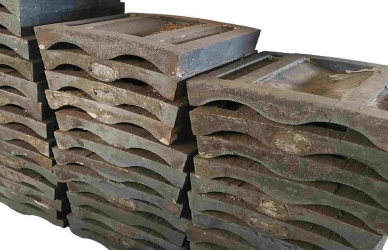

Our High-Chromium Alloyed Grinding Balls are engineered to deliver outstanding performance in demanding milling environments. Produced through advanced casting technology with adjustable chromium content (10–18%), these grinding balls offer high hardness, excellent wear resistance, and minimal breakage, making them ideal for fine grinding applications in mining, cement, chemical processing, and power generation.Each ball undergoes precise material selection, furnace smelting, thermal refining, oil quenching, and tempering to achieve a stable microstructure and long service life. Supported by high-precision spectrometer testing and strict quality control, our grinding balls ensure consistent performance and reduced downtime.Designed to withstand heavy impact and abrasion, Huihe’s High-Chromium Alloyed Grinding Balls help customers improve milling efficiency, optimize particle size reduction, and extend equipment lifespan—delivering reliable, cost-effective solutions for various mineral processing conditions.

Product Advantages

Excellent Wear Resistance

High chromium content (10–18%) ensures high hardness and strong abrasion resistance, allowing the balls to maintain shape and performance during long-term grinding.

Strong Impact Toughness

Optimized casting and heat treatment give the balls low breakage rates and stable toughness, making them reliable for high-impact milling environments.

Stable Quality & Consistency

Strict material testing and controlled production processes ensure uniform microstructure and consistent grinding performance across various industrial applications.

Application

Application1

Application2

Application3

Sustainability

Advanced Material Technology

Refined casting and quenching processes boost hardness and impact resistance, ensuring the balls maintain shape and performance under heavy abrasion and high-impact grinding conditions.

Extended Wear Life

High-Chromium Alloyed Grinding Balls benefit from improved alloy design and optimized heat treatment, resulting in significantly longer wear life. Their enhanced hardness and stable microstructure reduce downtime and maintenance costs.

Enhanced Engineering Optimization

Simulation-based analysis helps tailor grinding balls to specific ores and mill conditions, improving grinding efficiency and extending equipment lifespan across mining and industrial applications.

Company Advantage

Welcome to Huihe Miningparts High-Chromium Alloyed Grinding Balls! We are committed to delivering high-performance, wear-resistant grinding solutions for industries that demand durability and efficiency. In heavy-duty grinding environments, high-chrome grinding balls play a crucial role in ensuring stable mill operation, reduced wear, and long-lasting productivity.

Advanced Casting Technology

Our grinding balls are produced through strict alloy selection, furnace smelting, and thermal refining. Each ball undergoes element testing, oil quenching, and tempering, ensuring a stable microstructure and superior hardness.

Industrial-Grade Adaptability

High-chromium grinding balls are easily customized to suit various working conditions across mining, cement, and chemical industries. Their high wear resistance and toughness help optimize milling efficiency in demanding applications

Reliable Durability for Consumable Use

Designed for long service life, the balls significantly reduce equipment wear and lower maintenance costs. This makes them an ideal solution for industries seeking stable grinding performance and improved operational sustainability.

Strong Production Capacity

With stable furnace temperatures of 1540°C and optimized heat-treatment lines, we ensure precise chromium mixing and consistent quality. All products are inspected using high-precision OXFORD spectrometers for guaranteed performance.

Contact Us

Boasting a team of seasoned experts, while offering technical assistance and comprehensive one-stop solutions to the global marketplace.

FAQs

Related News

How To Properly Install Chromium Alloy Liners

Chromium alloy liners are essential components in many industrial grinding mills, providing superior protection to mill shells from wear and tear caused by grinding media and abrasive materials. Their high abrasion resistance, toughness, and long-lasting durability make them particularly suited for high-wear applications in industries like mining, cement, and quarrying.

Read MoreHow To Extend The Service Life of Ball Mill Liners ?

Ball mill liners are essential components that protect the mill shell from wear and tear caused by the constant friction and impact of grinding media and materials. These liners play a crucial role in enhancing the grinding process by lifting the grinding media, ensuring an efficient cascading action that improves grinding performance.

Read MoreHow To Choose Cement Mill Liners Based on Raw Material Hardness

Selecting the right cement mill liners is crucial for ensuring optimal mill performance, efficiency, and durability. The liners protect the mill shell from wear and tear caused by the grinding media and raw materials. One of the key factors in determining the appropriate liner material and design is the hardness of the raw materials being processed.

Read MoreThe Complete Guide To White Iron Mill Liners

White iron mill liners play a critical role in protecting the mill shell from the abrasive wear and tear caused by the grinding media and raw materials during the grinding process. These liners are specifically designed to withstand the high-impact forces and harsh conditions present in grinding mills.

Read More

Get Touch With Us

Contact Info

If you have any questions or requirements regarding solutions, please feel free to contact our customer service team.

+86-186-1677-4002

sales@huihemining.com